Cylinder Boring

Vertical fine boring - milling machine

BM200

- Introduction

- Specitications

- Features

- Accessories

- Required Space

- Photo Gallery

- Download

- Introduction

- Specitications

- Features

- Accessories

- Required Space

- Photo Gallery

- Download

The Vertical Fine Boring-Milling Machine BM200 has combined all functions and simple performance of the traditional Cylinder Boring Machine with the easy to-operate SJMC Easy Touch control system. Through the jont operation of the standard mechanical handwheel and the electronic handwheel, the boring of the cyinder body and the machining of the milling plane can be easily accomplished. With the excellent Easy Touch system, even a new hand can easily leam to operate the machine.

Model | BM200 | B200 | |

Control System | EasyTouch 3 Axis | Without | |

Boring Capacity | 200 mm | ||

Max. Boring Depth | 350 mm | ||

Max. Milling Area ( L×W ) | 300×900 mm | Without Milling | |

Spindle Speed | 50 ~ 1000 rpm stepless | ||

Spindle Feeding | 10 ~ 900 mm / min(0.01 ~ 0.2 mm / r ) | ||

Rated Torque of Boring at 50-500 rpm | 58 N.M | ||

Rated Torque of Boring at 500-1000 rpm | 22 N.M. | ||

Spindle Traverse | 600 mm | ||

Distance Between Spindle End Face and Work Table | 0 ~ 700 mm | ||

Distance between Spindle Axis and Carriage Vertical Plane | 380 mm | ||

Longitudinal Feeding of Work Table by Electric | 30 ~ 1200 mm / min | Hand Movement | |

Longitudinal Quick Travel of Work Table by Electric | 1200 mm / min | Hand Movement | |

Longitudinal Traverse of Work Table | 1200 mm | ||

Cross Traverse of Work Table | 100 mm | ||

Work Table Size ( L×W ) | 400×1350 mm | ||

Boring Accuracy | H7 | ||

Roundness for Boring | 0.005 mm | ||

Working Accuracy | Cylindricity for Boring | 0.015 mm / 300 mm | |

Flatness for Milling | 0.0127 mm / 305 mm | Without Milling | |

Surface Roughness | Boring | Ra 0.8 | |

Milling | Ra 0.8 | Without Milling | |

Power of Spindle Motor | 2 kW | ||

Motor Power of Work Table Movement | 0.4 kW | Hand Movement | |

Motor Power of Spindle Vertical Movement | 0.4 kW | ||

Overall dimensions ( L×W×H ) | 1870×1600×2000 mm | ||

Package Size | 2200×1450×2250 mm | ||

N.W. | 1900 Kg | ||

G.W. | 2300 Kg | ||

1.EasyTouch operating system

The left and right movement of the table, the up and down of the spindle, as well as the rotation of the spindle, are all driven by a servo motor, which by combing with the specific SJMC EasyTouch system, achieves the accurate numerical control of three-axis movement on the whole machine.

2.Small size to output high torque

BM160 is in compact design, with its working area of 1.5 ㎡ less than those of the similar machines. However, with maximum operating torque of 120N.M, its small size shows powerful processing capability. Due to BM160 spindle driven by 4kW servo motor and equipped with heavy load belt transmission system, the spindle is capable of a constant powerful torque output 120N.M at 200 to 500 RPM, and it can even maintain a constant output 100N.M at the higher speed of 500 to 780 RPM. The high torque output at high speed ensures the high efficiency of BM160.

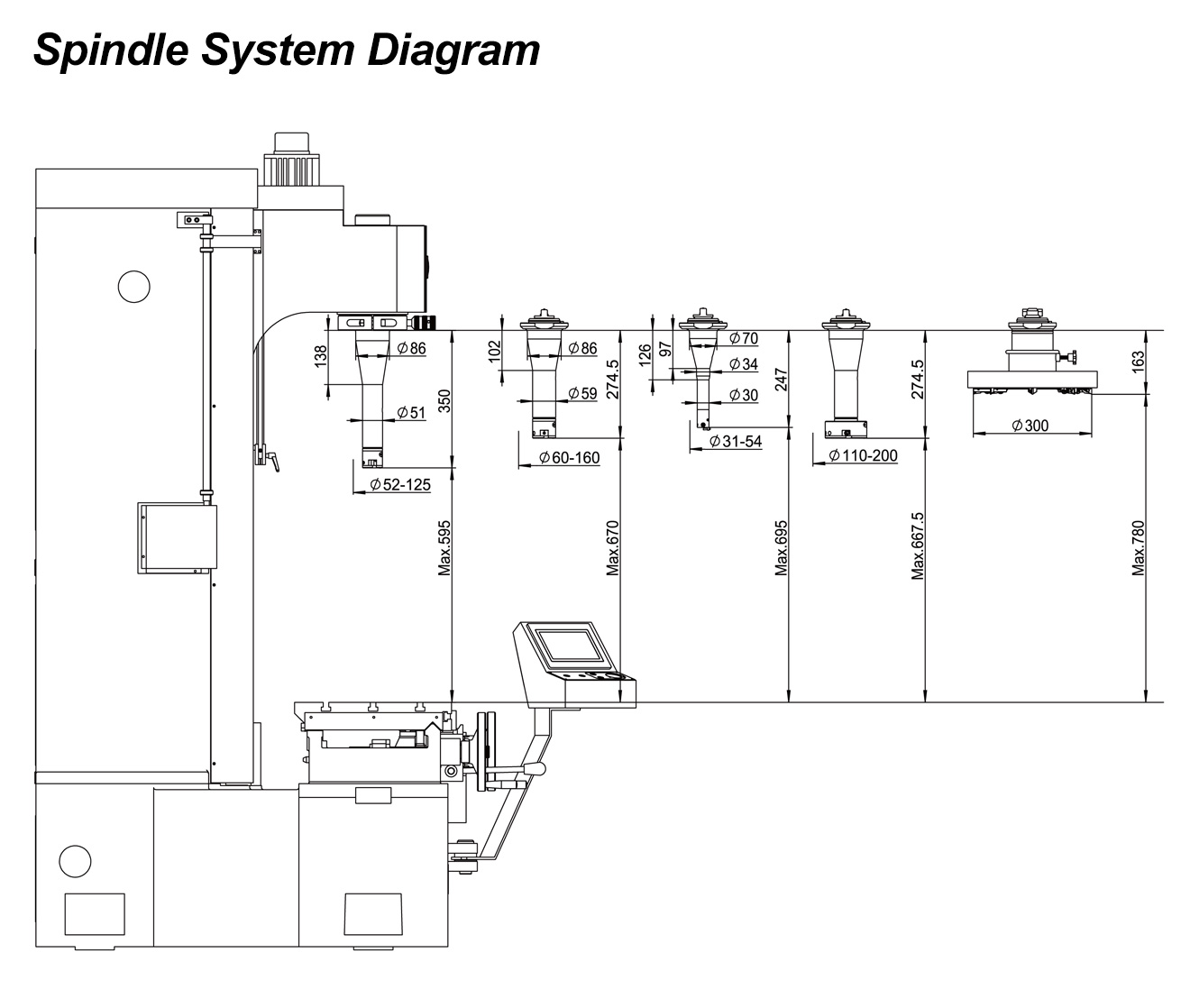

3.Precise and powerful spindle system

The deliberately designed spindle system with 3 spindles from small to large, you can hold one of which by one hand easily, plus the more artful quick change structure, contributes to the change of different spindle within 5 min by a person. Although the spindles are all exquisite, their cutting load capacities are strong. The penetration of a cutting tool at one side of MA52 and MA60 spindle can reach 1.5mm, with boring precision 0.005 mm.

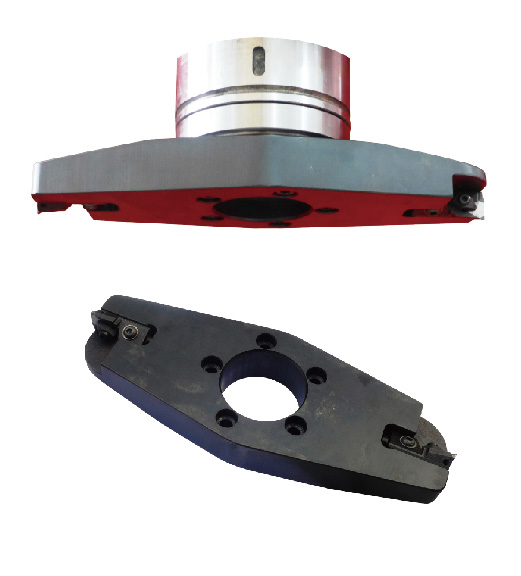

4.BM160 milling cutter is equipped with 8 cutters, and the milling feed at one time for facing is 1mm, so that no matter cast iron or aluminum part, the ideal surface roughness can be achieved. With flatness exceeding 0.013mm/300mm, its machining precision achieves the grounding effect and thus it can take the place of grounding with milling.

-

EasyTouch Control System for BM160

-

Optional Button Style Control Station

-

3 axis DRO.

-

MA52 Measuring Device for Setting Tool

-

MA52 Measuring DRO for Setting Tool

-

Tools Setting Guage on Spindle M30

-

Bore Gauge

-

Dial Gauge

-

Parallel Block

-

30°and 45°V-fixture for Boring and Milling

-

30°and 45°V-fixture for Boring

-

Univer Cylinder Head Fixture A

-

Quick Acting Fixture

-

Motorcylce Cylinder Fixture

-

Universal Cylinder Head Fixture B

-

Centering Device of Spindle

-

Boring Spindle MA52(φ52mm-φ125mm)

-

Boring Spindle MA60(φ60mm-φ160mm)

-

Boring Spindle MA110(φ110mm-φ200mm)

-

Boring Spindle MA30(φ31mm-φ54mm)

-

Surfacing Cutterhead (φ315mm)

-

Universal Adaptor for Milling Cutter

-

Bush with No.3 Morse Taper

-

CBN Triangular Insert

-

Tools Holder for Triangular Inserts

-

CBN Circular Insert for Iron Casting

-

PCD Circular Insert for Aluminium

-

Tools Holder for Triangular Inserts

-

Milling Head MP300 (φ300mm)

-

Tools holder and Boring Cutter

-

Assorted Hard Metal Insert with holder

-

Tools Grinder TG-III

-

Milling Setting Gauge

-

Spindle Stork

-

Table of Standard Acc. and Optional Acc.